Services

Serving you 24 hours a day, 365 days a year.

Comprehensive Maintenance Agreement

Consists of Maintenance Management (M1) and Comprehensive Spares Management (SA).

Planned Maintenance Agreement

Consists of Maintenance Management (M1) and Optional Spares Management (SP/SB/SC) to choose from.

Basic Maintenance Agreement

Consists of Maintenance Management (M2) and Optional Spares Management (SP/SB/SC) to choose from.

Heavy Work

General Checkup

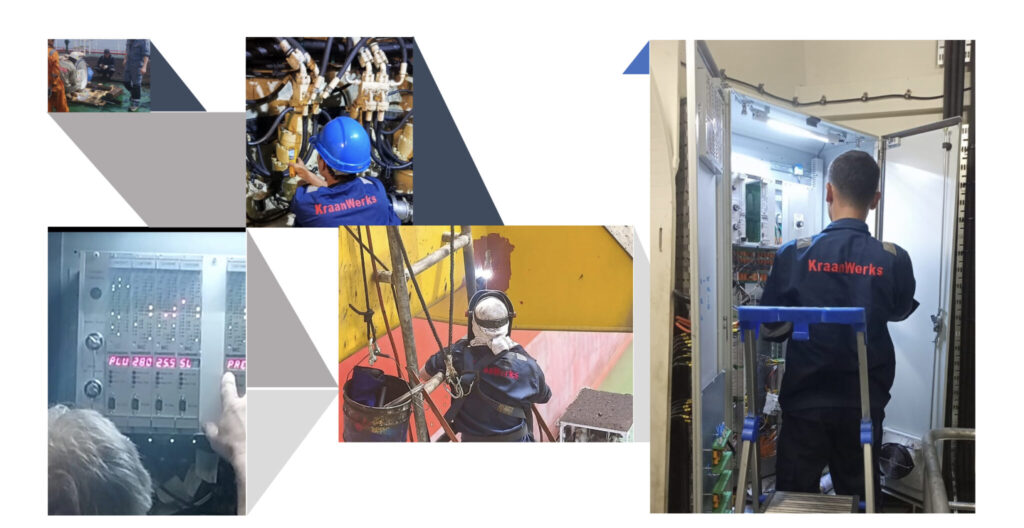

Troubleshooting and Repairs

In the event of crane breakdown, we provide remote technical support to our clients who have subscribed to our Maintenance Agreement. We have a Team of Crane specialists, this enables us to deploy them in short notice. With our fast response time, we help our customer to minimise the crane downtime.

Modernisation

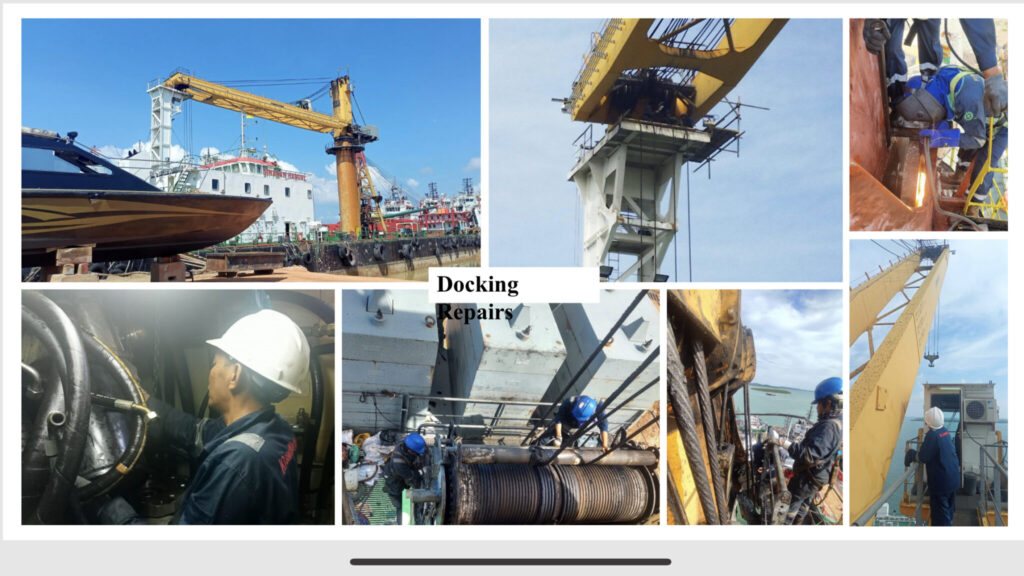

Docking Repairs

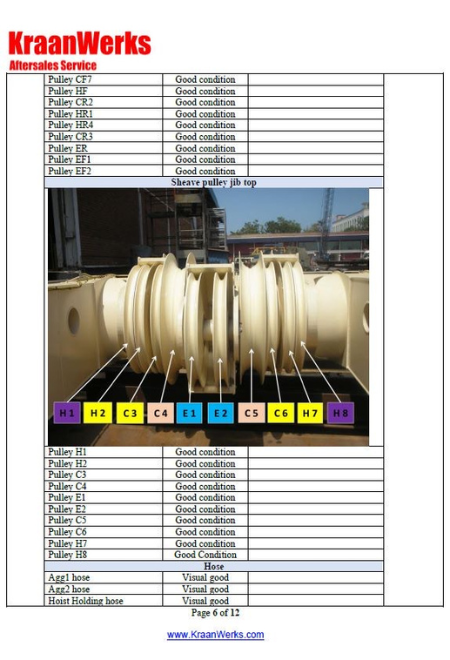

Our Heavy Work team besides performing all the Heavy Work services like slewing bearing replacement, winch replacement, wire sheaves replacement, electric motors servicing, PU1 & PU2 total refurbishment (MacGregor), Aggregate 1 & 2 total Refurbishment (LIEBHERR), hydraulic hose replacement, waterbag overload test etc. We have our project management team to oversee the progression of the repairs, provide prompt update to owners and provide detail updates of the development.

Get in touch

Our Locations

SINGAPORE OFFICE

KraanWerks Pte Ltd

UEN 202232623H

Website: www.KraanWerks.com

Email: enquiry@kraanwerks.com

Contact No: +65 6914 7734

BATAM OFFICE

PT. KraanWerks Indonesia.

Mega Regency Industrial Area Blok B No 01,

Kel. Sungai Binti, Kec.Sagulung